All Kinds of Pulley with Tone Wheel Equiped in Automobile Engine-OEM Manufacturing, Engine Parts, Dongfeng Plant Producting

Wuhan Dong Feng Motor Industry Imp. & Exp. Co., Ltd.- Certification:ISO

- Pulley Sizes:Type C

- Manufacturing Process:Casting

- Material:Aluminum Aolly, Carbon Steel

- Surface Treatment:Electroplating

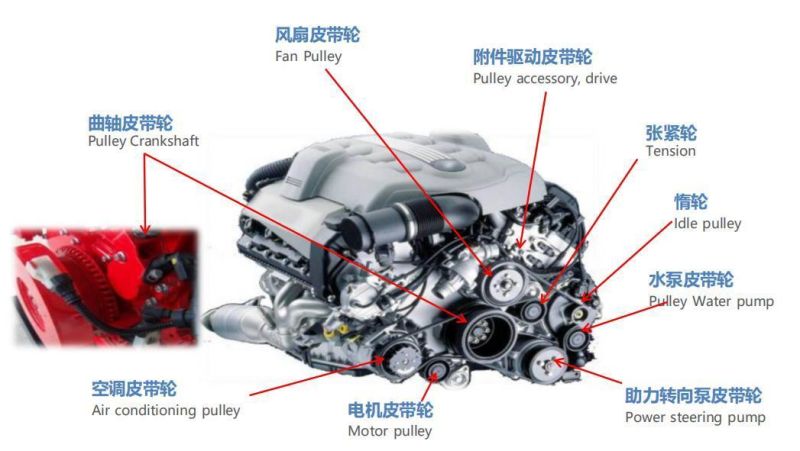

- Description:Crankshaft Pulley

Base Info

- Model NO.:OEM

- Coating:Cathode Electrophoresis

- Saltfog Resistance:500h

- Transport Package:Standard Export Packaging

- Specification:145*40mm

- Trademark:Dongfeng

- Origin:Hubei Province, China

- HS Code:84835000

- Production Capacity:10 Million PCS Per Year

Description

Basic Info.

Model NO. OEM Coating Cathode Electrophoresis Saltfog Resistance 500h Transport Package Standard Export Packaging Specification 145*40mm Trademark Dongfeng Origin Hubei Province, China HS Code 84835000 Production Capacity 10 Million PCS Per YearProduct Description

•Product Description:crankshaft pulley•Coating: cathode electrophoresis•Saltfog resistance: 500h•Size:φ145x40mm•current Customer: Cummins ExportOEM manufacturing according to customer's requirement and drawings.

1. factory profile- Dongfeng Spin

Founded in 2003

Assets: 59 million Yuan

Manufacturing Capacity: 10.0m pcs per year

Employee: 165

Area : 51400m2

Dongfeng Spin was founded on Sep 1, 2003. It is a professional producing company that specializes in pulley parts in Dongfeng Group.

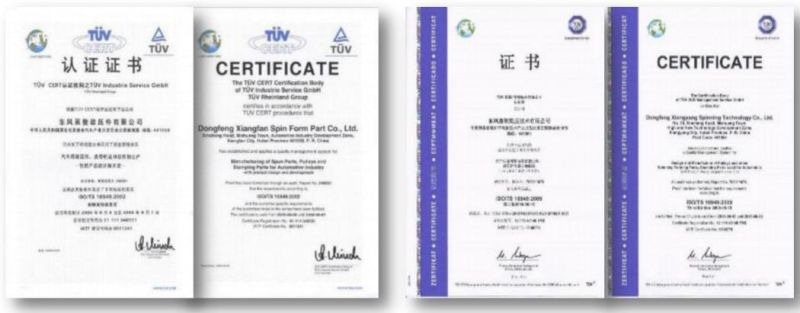

Dongfeng Spin passed TS16949 quality system by the third party in 2005, and passed IATF16949-2016 Certification of Quality Management System for Automobile Production Parts and Related Service Parts Organizations in 2018. In 2015 passed the GB/T280012011/OHsas18001:2007 security, occupational health system certification. GB/T24001-2004/ ISO14001-2004 environmental management system certification.

2. Technique Ability

-- We brought in spinning equipments and techniques from Germany in 1993, and mastered the complete set of spinning techniques.

-- We have accumulated rich experience in punching, machining, welding, spinning and painting during the long-term production.

-- We have 23 technical personnel, and 15 of those taking charge of R&D.

-- CAD-Computer-aided design

We apply two-dimensional software (TH-PCCAD &. TH-P3DM, etc.) to develop and design products. Meanwhile, we could provide Pro/E or UG three-dimensional drawing as per customer's requirement.

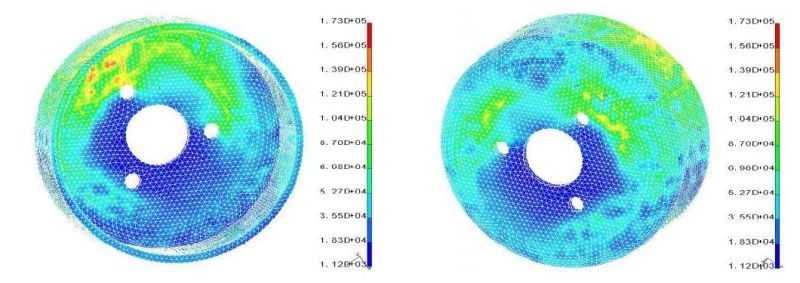

-- Finite Element Stress Analysis

We apply I-Deas software to analyze press of product.

-- Patent

-- Patent Our factory has a number of patented technology, such as the domestic double molding board spin & Aluminium magnesium alloy spinning technology. Those fill the technology blank.

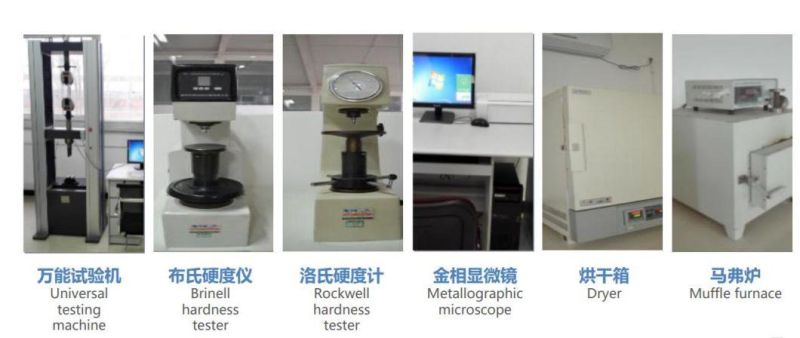

3. Quality Testing Capacity

4. Production Line

5. Main products

Main products based on different structure

6. Awards from customer

Awarded " Best 6 Sigma & Continuous Improvement" by Cummins EA IPO, Awarded "100% Delivery of Defect free part for 1st & 2ndQuarter "by CMEP, Awarded "Best Supplier in Corporation" by BFCEC. Awarded "Best Continuous Improvement & Quality Star" by DCEC

7. Certifications

7. CertificationsPassed TS 16949 Certificate in 2005, New Version of TS16949

Occupational Health Management System Certification GB/T28001-2011/OHsas18001:2007

Occupational Health Management System Certification GB/T28001-2011/OHsas18001:2007 Environmental management system certification GB/T24001-2004/ISO 14001:2004

Environmental management system certification GB/T24001-2004/ISO 14001:2004 Contact us: Wuhan Dong Feng Motor Industry Imp. & Exp. Co., Ltd. Department 2 (export business)

Contact us: Wuhan Dong Feng Motor Industry Imp. & Exp. Co., Ltd. Department 2 (export business)Mr. Deping LU (Export Director) Mr. Peng WANG (Project Manager)